December 2023

Inside the Newsletter:

New Director | Wastewater Energy | 2024 MnTAP Intern | Anesthetic Gas P2

Kelsey Klucas named Director of Minnesota Technical Assistance Program (MnTAP)

The Division of Environmental Health Sciences at the University of Minnesota’s School of Public Health is pleased to announce that Kelsey Klucas has been appointed as the next Director of the Minnesota Technical Assistance Program (MnTAP).

Kelsey holds a B.S. in Environmental Sciences, Policy and Management and an M.S. in Civil Engineering with a specialization in Environmental Engineering from the University of Minnesota. She brings to this leadership role extensive private sector experience where she worked as an environmental engineer for an environmental consulting firm, and at the 3M Company where she addressed global environmental compliance.

Kelsey has served as a staff engineer at MnTAP since 2022 where she has focused on developing MnTAP capacity to address PFAS pollution, co-lead projects related to metal fabrication and finishing, and developed proposals for expanding MnTAP’s work in environmental justice. With Kelsey’s leadership we look forward to MnTAP continuing its 40+ year legacy of innovative service to Minnesota by helping businesses reduce pollution and conserve energy and water.

Please join us in welcoming and congratulating Kelsey!

Kelsey Klucas – Director

612-624-4619

kluc0035@umn.edu

Wastewater Energy Efficiency Training

Since 2021, the Minnesota Technical Assistance Program (MnTAP) has been offering operator training focused on identifying and implementing low and no cost improvements that reduce energy consumption at wastewater treatment plants (WWTPs), without sacrificing plant effectiveness at meeting discharge limits. The training is targeted at wastewater treatment plant operators at municipal mechanical treatment WWTPs. Operators receive 16 direct wastewater contact hours by completing this MPCA accredited course.

Since 2021, the Minnesota Technical Assistance Program (MnTAP) has been offering operator training focused on identifying and implementing low and no cost improvements that reduce energy consumption at wastewater treatment plants (WWTPs), without sacrificing plant effectiveness at meeting discharge limits. The training is targeted at wastewater treatment plant operators at municipal mechanical treatment WWTPs. Operators receive 16 direct wastewater contact hours by completing this MPCA accredited course.

To date, MnTAP has conducted six cohorts, including 33 WWTP operators. As a result, an annual 1,560,000 kWh of energy savings has been implemented at WWTPs for annual cost savings of $132,800.

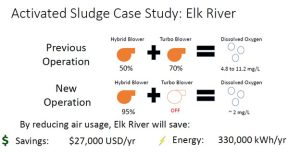

Below is a case study from the Elk River Wastewater Treatment Plant. Operators, Andy Kitzman and Jason Ames, provide a great example of the energy savings that can be achieved through our training.

Activated sludge refers to a common process at wastewater plants that uses blowers to provide air to foster biological activity that breaks down organic pollutants. This process typically requires that the dissolved oxygen (DO) level be maintained at 2 mg/L or greater. Plants with a DO level greater than 2 mg/L often have an opportunity to save energy by decreasing aeration. As shown above, the Elk River WWTP uses both a turbo and hybrid blower at default variable frequency drive (VFD) speed setpoints of 70% and 50%, respectively, to provide air to the activated sludge process. This resulted in dissolved oxygen (DO) in their activated sludge process ranging from 4.8 mg/L to 11.2 mg/L. Operators Jason and Andy switched their system from manual control to DO control with a target of 2 mg/L and prioritized operating the smaller hybrid blower which ran at a maximum of 95% speed most of the time. This resulted in the average power consumption of the blowers decreasing by 330,000 kWh/yr of energy for an estimated savings of $27,000 per year.

We are currently recruiting wastewater operators to join our winter 2024 cohort. This cohort will be hosted in and around the metro region of Minnesota. The following chart gives the schedule for the upcoming cohort:

| Date (All Wednesdays) | Activity* | Description | Time |

| January 31, 2024 | Module 1 | Benchmarking Analysis Using B3 | 9:00AM – 2:00PM |

| February 14, 2024 | Modlue 2 | Secondary Treatment Analysis & Training | 9:00AM – 2:00PM |

| February 28, 2024 | Call 1 | Conference Call: Review Onsite Results | 9:00AM – 10:00AM |

| March 13, 2024 | Module 3 | Biosolids Handling Analysis & Training | 9:00AM – 2:00PM |

| March 27, 2024 | Call 2 | Conference Call: Review Onsite Results | 9:00AM – 10:00AM |

| April 10, 2024 | Module 4 | Continuous Improvemnt | 9:00AM – 2:00PM |

*Modules 1 through 4 are in person trainings that will include a light breakfast and lunch.

If interested, Contact:

Kira Peterson – Engineer

612-624-4653

kira@umn.edu

Apply for Your 2024 MnTAP Intern!

In case you missed it, MnTAP Solutions was published in November and highlights the successful projects from the 2023 MnTAP Intern Program. Amazing results! So, before you do anything else today, click this link to Apply Now for a 2024 MnTAP Intern at YOUR facility. Even if you are not certain about the project you would like to do, MnTAP can work with you to develop a great opportunity for your site. The important part is to start the process NOW!

In case you missed it, MnTAP Solutions was published in November and highlights the successful projects from the 2023 MnTAP Intern Program. Amazing results! So, before you do anything else today, click this link to Apply Now for a 2024 MnTAP Intern at YOUR facility. Even if you are not certain about the project you would like to do, MnTAP can work with you to develop a great opportunity for your site. The important part is to start the process NOW!

The MnTAP Intern Program pairs manufacturing, food processing, hospitality, and other facilities in Minnesota with a college student who researches and recommends water conservation, energy efficiency and pollution prevention solutions. MnTAP interns have helped identify opportunities that save participating companies millions of dollars annually.

If your company could use another set of eyes to achieve similar results, now is the time to start developing a project for the summer of 2024. We anticipate supporting 15-18 projects that could focus on water conservation, energy efficiency, sustainable chemistry, solid waste, and pollution prevention.

Proposals are currently being accepted and will be reviewed upon receipt. Companies will be contacted by MnTAP technical staff within two weeks of submission for additional project development and scoping. Although proposals are accepted through January 2024, companies are encouraged to apply by the end of 2023 to provide enough time to scope a well-defined project at their facilities.

For more information about the intern program or the application process, visit the MnTAP Intern Program webpages for Businesses. Use the Apply link to the Intern Project Proposal form.

For More Information, Contact:

Matt Domski – Intern Program Manager

612-624-5119

mdomski@umn.edu

Anesthetic Gas Pollution Prevention

In the United States, the healthcare sector is responsible for 10%¹ of total greenhouse gas (GHG) emissions. One of the leading sources are anesthetic gases. Anesthetic gases are used in hospitals, dental offices, vet clinics, and what many may not realize is that these gases are very potent GHGs. Below are the most common anesthetic gases with their respective global warming potentials (GWPs). GWPs represent how many times more potent they are than carbon dioxide:

| Gas or Compound | Global Warming Potential (GWP) |

| Sevoflurane | 130 |

| N2O | 298 |

| Isoflurane | 510 |

| Desflurane | 2,540 |

To compound this issue, leak rates of 75-90% are common in central line systems for anesthetic gases such as nitrous oxide². These leaks occur throughout the piping network that is in the floors and ceilings, making these leaks difficult to identify.

There are many potential solutions including decommissioning central lines systems and replacing them with mobile units, as well as switching to a substitutable anesthetic with a lower GWP if one currently exists.

For More Information, Contact:

Logan Wikstrom – Associate Engineer

952 – 607 -1106

wikst043@umn.edu