September 2020: An Ounce of Prevention…Can be Worth Pounds of Savings

Inside the Newsletter:

P2 Week | Intern Symposium Success | Intern Presentations | eTRU Cleaning the Air | RAM Webinar Series

Celebrating Pollution Prevention Week

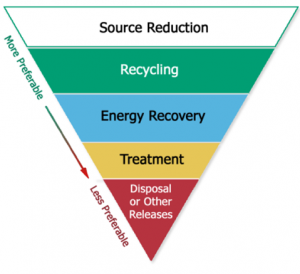

MnTAP, the Minnesota Pollution Control Agency and the U.S. EPA are celebrating 30 years of pollution prevention (P2) during Pollution Prevention Week, September 21-27! Pollution prevention week is celebrated annually in September to remind everyone about the environmental and economic benefits of P2. P2 refers to avoiding waste and toxic materials from the start, instead of trying to clean them up later. This approach is best for the environment, because it uses less resources and decreases risk of health or environmental damage. Typically, pollution prevention also saves money by buying less and eliminating treatment and disposal costs.

The Minnesota Pollution Control Agency’s P2 Week communications feature examples where they support partners by going beyond monitoring and controlling pollution to preventing it in the first place. MnTAP offers P2 advice and technical assistance to businesses and organizations throughout Minnesota every day!

Many people are familiar with the saying “reduce, reuse, recycle” but the focus is often on recycling. Reduce comes first, because it’s actually the most important as it provides the most environmental impact! The benefits of waste reduction are due to the need for less material, energy and water inputs as well as decreasing the need for disposal. Combined the impact of waste reduction saves businesses and individuals money.

For example, making a disposable, single use water bottle from new materials utilizes substantial energy and materials for extraction of raw materials, production and transport. Making a disposable single use water bottle from recycled plastic uses 45% less energy and 20% less water compared to the bottle made from new plastic, plus it eliminates the solid waste from previous bottles. However, avoiding the bottles altogether and using a container you already have eliminates all of the energy, water and other impacts from extraction, manufacture and transport! Plus, it saves money!

Optimizing material use and reducing waste can make your operation more efficient and result in cost savings for purchasing, handling and disposal. The following steps can help guide your waste reduction efforts.

- Understand what’s in your trash through a waste assessment or sort

- Reduce waste at the source by changing procedures, processes, and products

- Reuse excess materials at your facility or through the MN Materials Exchange

- Purchase environmentally preferable (“green”) goods

- When reduction is not an option, maximize recycling

In addition to the production floor, here are some things you can do in your home or office to prevent pollution and waste at the source:

- Don’t buy bottled water. Use reusable bottles or cups to get water from the tap.

- Don’t print out documents unnecessarily – save the paper, and the trees and energy that went into making it!

- Save energy by selecting computers, lighting, and appliances that have earned an ENERGY STAR label, and turning them off when not in use.

- Choose cleaners and other products labeled with EPA’s Safer Choice logo for safer chemical ingredients without sacrificing quality or performance.

- Even during this time of increased focus on disinfecting, you can select products with safer active ingredients that are effective against COVID-19.

MnTAP would be happy to help your Minnesota business look for ways to prevent pollution, during P2 week, or anytime! Site assessments can be conducted in person or virtually, and our services are confidential, non-regulatory and no cost to you! Email mntap@umn.edu or call 612-624-1300 and leave a message. A MnTAP pollution prevention specialist will help you start your P2 journey.

MnTAP Intern Symposium – A Resounding Success

The Minnesota Technical Assistance Program was honored to host the 2020 MnTAP Intern Symposium on August 19, 2020. The event featured presentations on the work 21 interns and student researchers accomplished since June 1. These projects sought to identify and implement operational changes to enable businesses to create less waste, use fewer hazardous materials, require less water and energy to deliver high quality products and services to market and save money.

The 2020 MnTAP Intern Program student cohort, their advisors and host companies showed exceptional resilience as we re-invented the program from our traditional format to what it needed to be during the Covid-19 pandemic. From virtual interviews and training sessions, hybrid work arrangements and ultimately a fully online symposium the 2020 program was designed to provide safe work options for the largest number of interns and student researchers MnTAP has ever supported. Some aspects of the Intern Program did not change, specifically, the opportunity for students to use their educational background and passion to improve the world, to lead projects focused on making business justified recommendations, and to enhance business sustainability performance.

The companies who host the MnTAP Interns represent a wide range of industries including: food and beverage, foundry and metal fabrication, a variety of manufacturing sites, facility management, coatings and paper production as well as municipal wastewater treatment and water supply facilities. Geographically these projects impact communities from the far northwestern part of the state in Warroad, Breckenridge, Karlstad and Roseau to the south central communities of Owatonna and New Ulm. A preliminary compilation of the impact of the 87 recommendations when implemented includes:

- 2.4 million lb of solid waste and hazardous material reduction

- 41 million gal of water reduction

- 21 million kWh of electric energy

- 150,000 therm gas energy

- $3 million in potential first year savings

To date 32% of the recommendations are implemented or in the process of being implemented.

Contact Matt Domski for more information.

Intern Presentations are Available for Review

MnTAP Interns focused on pollution prevention, source reduction and energy/water efficiency. The presentation slides for the 2020 intern program have been posted on the MnTAP website under 2020 Intern Projects. To review an individual project folder click the links below. Folders contain the project abstracts and a copy of the Symposium presentation slides. Project Executive Summaries and presentation video will be posted as available over the coming weeks.

MnTAP Interns and Student Researchers:

Mapped facility water use and identified opportunities for efficiency.

- Lifecore Biomedical mapped water intensive processes, identifying reduction options.

- Abbott identified process water savings to help meet corporate efficiency goals.

- Old Dutch Foods minimized water to wash/process potatoes and corn for high quality chips.

- MnTAP analyzed industrial data and identified common opportunities for water savings.

- MN Department of Administration found water savings in irrigation and building fixtures as well as energy savings in compressed air and lighting systems.

Analyzed and identified significant industrial energy efficiency:

- St. Croix Forge minimized energy use and scrap rate in targeted operations.

- Pearson Candy Company focused on optimizing run time and increasing equipment efficiency.

- The University of Minnesota Physicians contributed to site goal of 25.5% in the EUI.

- Post Consumer Brands analyzed upgrade options for boiler systems and compressed air use.

- Municipal Water Treatment summarized efficiency opportunities from site interviews and developed targets for assessments.

Researched and implemented solid, hazardous and non-hazardous waste reduction opportunities:

- Minnesota Specialty Yeast used modeling and testing to decrease reliance on phosphoric acid.

- Rust-Oleum identified industrial cleaning alternatives to reduce hazardous chemical waste.

- Sappi improved waste reduction and segregation as well as compressed air systems.

- Bosch Automotive Service Solutions improved organization of pallets and reduce waste.

- August Schell Brewing explored options to reduce wastewater load and reuse process water.

Recommended changes to wastewater plant and pond operation to optimize nutrient reduction:

- Wastewater treatment Ponds at Karlstad and Breckenridge modeled impact of retention time, chemical additives and other strategies on effluent nitrogen and phosphorus.

- Wastewater Treatment Ponds at Roseau and Warroad modeled impact of operational changes and waterfowl management strategies on effluent nitrogen and phosphorus.

- Otsego Wastewater Treatment modeled use of an external carbon source, aeration cycling, and tank size variation with optimization of other parameters to decrease effluent nutrient.

- Albert Lea Wastewater Treatment modeled optimization of sludge age and aeration as well as operations configuration to reduce nitrogen and phosphorus in effluent.

Contact Matt Domski to get more information about participating in the 2021 MnTAP Intern Program.

Cleaning the Air – A Multitude of Benefits from Transport Refrigeration Unit (TRU) Electrification

What is a transport refrigeration unit, aka TRU? A TRU is an air conditioning unit for a box truck or trailer. It usually relies on a diesel engine and a compressor to keep the refrigerated products we buy, cold during transport. These TRUs spend a portion of their daily operating time stationary, cooling down, loading, and unloading product. This time spent at a dock door or in the yard is time that the TRU is operating with diesel, which is noisy, expensive, and emission producing.

Running the TRU with electricity instead of diesel during these stationary operational times using an electric capable TRU and shore power is a well-developed alternative. This system consists of two major components, the electric capable TRU which can easily switch between diesel and electric operation and the shore power infrastructure which supplies the TRU with electricity. The operational cost reduction by running a TRU with electricity during stationary operation was proven in Oregon and California by our partners CleanFuture. The question we set out to answer was whether this success could be replicated in Minnesota.

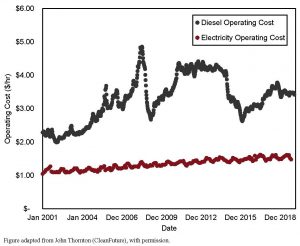

The first major goal was to quantify the savings potential of this opportunity and determine the financial feasibility with Minnesota’s climate and utility prices. Project partners found electric operation of a TRU provides a lower and more stable operating cost than diesel operation.

Figure adapted from John Thornton (CleanFuture), with permission. Data gathered from EIA using Midwest diesel and electricity prices.

The figure above shows a $1 – $4 per hour difference between diesel and electric operation, here in the Midwest, with a current difference of approximately $1.50 per hour. This difference in operating cost comes with the added benefit of cost stability, only seen with electric operation. This analysis indicates there is an opportunity for cost savings with electric operations while stationary at the dock.

To get an idea of stationary run time Minnesota partners set up tracking software on three trailers to track the amount of time each TRU spent operating stationary at the dock or yard versus how much time was spent operating on the road. On average, each TRU spent about 50% of its operational time stationary, cooling down, loading, or unloading products. This backed up the work that CleanFuture did in Oregon and California.

The total capital cost for these projects is broken down into two pieces: the electric capable TRU and the shore power infrastructure which includes the plug and the infrastructure to electrify that plug. Where this technology is most economically attractive is when the fleet already has electric capable TRUs, but does not have the shore power infrastructure, or if the fleet is replacing TRUs on a set schedule and would incur a small incremental cost of upgrading their new TRUs to electric capable. With these two options, paybacks for these projects fall below 2 years.

What became evident was that if a fleet needed to purchase all of this equipment to enable dock or yard electrification there is a significant up front cost. Purchase of both the electric capable TRU and the shore power infrastructure is an investment of $35,000 – $45,000. This results in a payback period of 10-20 years with the estimated energy savings and the funding that exists from the Diesel Emission Reduction Act (DERA). Without additional financial assistance, this level of investment in the required infrastructure is a major hurdle for small local fleets.

Learn more about this technology and where it has been implemented locally by viewing a recorded webinar presented by the Minnesota Trucking Association (MTA) which is posted on the MnTAP TRU webpage along with additional information on DERA funding and project details.

Recycling and Reuse Webinar Series

The Recycling Association of Minnesota (RAM) is hosting a webinar series with the Minnesota chapter of the Solid Waste Association of North America and the Minnesota Solid Waste Administrator’s Association. The series will consist of 10 webinars, taking place on Thursdays from September 10th to November 12th. Each webinar will focus on a different topic related to recycling, reuse, and waste disposal. Register and read more about the series.