June 2020

Inside the Newsletter:

Minnesota Legislature Enacts TCE Ban | Minnesota Businesses are Working to Replace TCE | What Can I do to Eliminate TCE | Financing Your Transition from TCE | Reopen with Minnesota Materials Exchange | Vision for a Circular Future | Salt Symposium

Minnesota Legislature Enacts Nations’s First TCE Ban

Trichloroethylene (TCE) is an industrial solvent used in manufacturing that has been linked to negative health effects, including cancer. During the 2020 legislative session, Minnesota became the first state in the country to enact a partial ban of TCE effective June of 2022.

Below are a few key points about Minnesota’s partial ban from the MPCA:

- The ban will apply only to sites required to have an AQ Permit from the MPCA – it is not a comprehensive statewide ban.

- It will be effective in June, 2022; though businesses with less than 500 employee may apply for an extra year.

- Sites that are ‘conditionally exempt facilities’ (and thus are not required to obtain an AQ Permit if they instead follow technical standards) are not subject to the ban.

- Sites that are ‘insignificant facilities’ (below AQ Permit thresholds) are also not subject to the ban.

- While most larger hazardous waste generators will be subject to the ban, many small businesses will be outside its scope.

- Text of the new law is available at: Minnesota Legislature

- An overall summary of MPCA AQ Permitting is at: MPCA Types Of Air Permits

- A review of ‘conditionally exempt facilities’ is available at: MPCA Conditionally Exempt Facilities & Technical Standards

- A review of ‘insignificant facilities’ is available at: MPCA Insignificant Facilities

MnTAP has been engaged in a project with the University of Massachusetts’s Toxics Use Reduction Institute to find safer alternatives to trichloroethylene (TCE). To help businesses throughout the state determine if they use TCE and find safer solutions, MnTAP has put together a suite of no cost technical assistance resources to facilitate a safer switch away from TCE. See the articles below introducing a series of training webinars to understand the use of, and alternatives for TCE. Additionally, no cost, site specific technical assistance and alternatives testing is available to any site that wants to.

Minnesota Businesses are Working to Replace TCE

MnTAP is working with Minnesota TCE users to find and implement the best alternatives to replace TCE and meet their process needs. So far, we have engaged nine industrial TCE users to participate in the project, representing over 85,000 lbs/year of TCE reduction opportunity. One company is in the process of implementing a new alternative process, and has already eliminated 3000 lbs TCE annually. The other companies are in various stages of sample collection and testing.

Although most companies use TCE for vapor degreasing, none of the vapor degreaser compatible products that are marketed as replacements for TCE are considered safe enough to be a switch. These include n-propyl bromide (nPB) and a variety of trans-dichloroethylene (t-DCE) blends sold under the brand names Tergo, Ensolv, Fluosolv, and Novec. Instead, we are working with companies to test and implement options that will be truly safer for the long term, including non-chlorinated solvents such as dimethyl glutarate, glycol ethers, and modified alcohols; aqueous cleaners such as Liquinox and Method laundry detergent; and biobased cleaners such as Ozzy Juice.

If your company currently uses TCE, you can receive no-cost technical assistance and testing to identify a safer solvent or cleaning system that meets your process needs. Join the increasing number of companies that are making a positive step to eliminate this hazardous solvent from their facilities.

For more information on how you can participate in the TCE Alternatives project, you can contact Jane Paulson (janep2@umn.edu, 612-624-1826), or view recordings from our June 2019 training event on the MnTAP website. The training includes information on the project, pros and cons of potential TCE alternatives, tools for hazard assessment, and case studies from companies who have successfully eliminated TCE from their process.

This project is a partnership with the Toxic Use Reduction Institute (TURI) at the University of Massachusetts Lowell, and made possible by funding through an EPA/MPCA Pollution Prevention Partnership grant and the Supplemental Environmental Project agreed to in the Stipulation Agreement between Water Gremlin and the Minnesota Pollution Control Agency.

What Can I do to Eliminate TCE From My Operations?

Beginning the week of June 16th, 2020, MnTAP will initiate our trichloroethylene (TCE) video series. The series is intended to provide education and resources to Minnesota industries following the recent state legislation that bans the use of TCE in facilities with state-issued air quality permits. This ban includes TCE used in manufacturing operations, processing or cleaning processes. The legislations requires facilities to have a replacement for TCE that is a chemical proven to be safer and less toxic by June 1, 2022.

The TCE educational series will consist of eight short (<5 min) videos delivered weekly. The goal of this series is to provide assistance in TCE identification and elimination in Minnesota facilities through reliable information and access to technical assistance resources. The topics will range from more information on the recent state ban and the health and environmental hazards of TCE to outlining the steps to replace TCE and how to identify safer options. We will also provide information on how to join MnTAP’s TCE Alternatives Project, which is free, confidential and non-regulatory assistance.

Help in Financing Your Transition From TCE

A grant program, funded by Ramsey/Washington Recycling & Energy and administered by Environmental Initiative, has been launched to help businesses in Ramsey County reduce perchloroethylene (PERC) or volatile organic compounds (VOCs) including TCE. Businesses can receive free technical assistance and financial support of up to $50,000. This funding can be used to help transition to safer, more sustainable chemicals, to purchase modern, high efficiency equipment, or to safely decommission old equipment that contains hazardous chemicals.

These grants can be used together with the MPCA Small Business Loan Program. The MPCA provides loans at zero-percent interest to small businesses for capital equipment purchases that help the company meet or exceed environmental regulations.

To quality, a borrower must be an existing small business corporation, sole proprietorship, partnership, or association with:

- Less than 100 full-time employees

- An after-tax profit of less than $500,000

- A demonstrated ability to repay the loan

Recycling with COVID-19

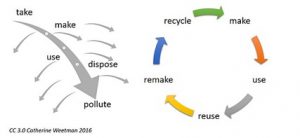

The COVID-19 pandemic has forced consumers across the world to think about their consumption differently, asking themselves if the things they already own could be reused or repaired in some way to make them valuable again. Two brands – Levi’s and Dell – have been thinking in this way already. They have been working to reuse materials from within their supply chain to create new products that will cause less damage to the environment.

A group called the Minnesota Sustainable Growth Coalition is doing similar work. Made up of businesses that call Minnesota home, the coalition addresses issues in materials waste, clean energy, and water in order to progress the state of the circular economy within Minnesota. Learn more about the coalition and the possibility of becoming a member.

Learn about the Minnesota Materials Exchange

ReUSE MN Vision for a Circular Future

Reuse, rental, and repair play an essential role in supporting and stabilizing sustainable, local economies and communities. Now more than ever, we’re seeing the limitations of our existing supply chains and the harmful impacts of our consumption patterns. We need to move away from the linear status quo to a circular, regenerative model.

This virtual conference opens the opportunity for broader connection, and access to information and speakers from around the country. ReUSE Minnesota is excited to bring an interactive and energizing experience to you, and continue efforts to grow the national reuse movement.

Register Now! – Early Bird Rates Expire June 26, 2020

Session topics will center on reuse, rental, and repair efforts, and strategies that support the development of these sectors related to the following topics.

- Sustainable Consumption

- Climate Connections

- Community Impacts

- Equity & Social Justice

- Marketing, Media & the Consumer Experience

- Business Infrastructure & Organizational Best Practices

- Extending the Life of Products (Design, Materials, Services)

- Reuse in the Building Sector

See the preliminary Schedule at a Glance

Conference website

Fortin Consulting Salt Symposium – August 4 – 5, 2020

Fortin Consulting Inc. is sponsoring the Salt Symposium 2020. This live streamed symposium will shape the chloride conversation, presenting developments in salt use optimization for people and the environment. Presentation focus:

- Day 1 – Chloride use in water softening, fertilizer, and dust suppressants.

- Day 2 – Latest developments in chloride reducing approaches for winter maintenance.

Keynote addresses and award presentations on both days.

Join on August 6, 2020 for FREE Smart Salter Training Classes