May 2021

Inside the Newsletter:

Interns 2021 | Water Efficiency Projects | Metal Fabrication | Gabrielle Martin | Salt Symposium | 2021 Intern Symposium

The 2021 Intern Program Has Launched!

For the 2021 MnTAP Intern Program we are hosting a mix of research projects and traditional MnTAP Intern projects at facility sites. This cohort of 15 young professionals is comprised of students from University of Minnesota, Twin Cities, University of Minnesota, Duluth, University of Wisconsin, Madison, and St. Thomas University. These interns bring expertise from the fields of Chemical Engieering, Chemistry, Mechanical Engineering, Bioproducts and Biosystems Engineering, Biomedical Engineering, Computer Science and Political Science/Sustainability Studies.

For many companies, tackling energy efficiency, waste reduction, and water conservation projects can be challenging. Pressing demands, such as production concerns or a lack of human and capital resources, can make it difficult for businesses to research and analyze potential opportunities for waste reduction. That’s where MnTAP interns can help. With a highly qualified intern dedicated solely to their project, companies have been able to address efficiency concerns fast with incredible results.

During their 12-week summer appointment, interns will analyze current processes, investigate alternatives, define best management practices and offer cost-saving strategies to reduce water usage, conserve energy, reduce waste and improve process efficiency to help meet business environmental and cost savings goals. The 2021 MnTAP Intern cohort completed their virtual training and will begin project work at the end of May or early June. We look forward to the possibility gathering for the Intern Symposium on August 18, 2021.

Funding partners include Legislative-Citizen Commission on Minnesota Resources (wastewater nutrient reduction), Metropolitan Council Environmental Services with funding from the Clean Water Land and Legacy Amendment (water conservation), Minnesota Pollution Control Agency (pollution prevention), Minnesota Pollution Control Agency and EPA Region 5 (pollution prevention), Xcel Energy (energy efficiency). With this partner support, interns will work with companies across the state to help them uncover pollution prevention, waste reduction, and, water and energy efficiency opportunities.

Water Efficiency Projects

Although Minnesota has an abundant supply of clean water, the costs and impacts of consuming water can add up quickly for companies. With the economic and environmental impacts in mind, many businesses are considering how to conserve more water in their operations and improve the efficiency of their facilities. MnTAP strives to help companies optimize water use to save money, avoid additional charges, and reduce environmental impact. This summer MnTAP interns are mapping facility water use and identifying opportunities for efficiency.

Although Minnesota has an abundant supply of clean water, the costs and impacts of consuming water can add up quickly for companies. With the economic and environmental impacts in mind, many businesses are considering how to conserve more water in their operations and improve the efficiency of their facilities. MnTAP strives to help companies optimize water use to save money, avoid additional charges, and reduce environmental impact. This summer MnTAP interns are mapping facility water use and identifying opportunities for efficiency.

Here are several projects with significant water efficiency components:

- General Mills in Golden Valley is hosting an intern to lead a project to reduce water use at a food R&D center.

- Great Lakes Coca Cola in Eagan is hosting and intern to identify water conservation opportunities at a beverage bottling facility.

- JIT Powder Coating in Farmington will be identifying ways to manage water and wastewater at a powder coating manufacturing operation.

- MnTAP is hosting our own intern focused on developing a database and related search protocols to implement a searchable, web-based water conservation/efficiency tool.

- National Sports Center in Blaine will seek water and energy efficiencies at a Minnesota sports complex.

- Living Greens Farm in Faribault is focusing on projects to improve on water efficiency, energy conservation, and waste reduction.

- Faribault Woolen Mills in Faribault is seeking to map how water is used in their process and identify opportunities to decrease process water intensity.

Metal Fabrication Efficiency Measures

Best Practices in Metal Manufacturing

MnTAP, in collaboration with the Minnesota Precision Manufacturing Association (MPMA), set out to get to know the metal manufacturing industry a little better. This work began in January 2021 with funding from an EPA Region 5 Pollution Prevention Grant. Metal Manufacturing and Fabrication is an important industry sector In Minnesota, with more than 1,000 machine shops that employ over 10,000 people and generate more than two billion dollars in annual sales. Six companies and three vendors stepped up to tell their side of the story. These Minnesota companies take a lot of pride in what they do; technology and lean practices are keeping them competitive while reducing energy and waste.

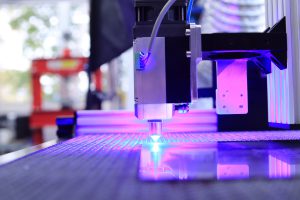

Jones Metal Inc. – Improved Laser Cutting Enhances Business Performance

Since 1942 Jones Metal has been a fully integrated precision metal fabricator for a variety of industries. With the goal of becoming the most technologically advanced fabricator in the region, they understand the importance of investing in state of the art equipment to maximize productivity and keep costs down. They have focused their success on the benefits of understanding laser technology.

Laser cutting emerged for the purpose of cutting sheet steel in the late 1960’s. The CO2 laser generates a laser beam that shoots from the generator through a series of mirrors to intensify the beam before reaching the material. The beam loses power each time it hits a mirror, resulting in an energy loss of approximately 25% once it reaches the material. A newer technology uses a fiber optic cable. The beam generated in a fiber laser travels through a fiber optic cable as opposed to a series of mirrors. The primary advantage is minimal energy loss as the beam travels through the cable, resulting in maximal cutting power at the material and lower energy consumption.

Based on 1000 hours of annual operating time, the new fiber laser would save 20,000 kWh/yr while enabling twice the throughput. Using a utility rate of $0.08/kWh this equates to a savings of $1,600 annually in energy savings. The increase in production improves customer satisfaction, on-time delivery of the product, and overall bottom line.

Tell us Your Story!

MnTAP has hired a summer intern to continue the work of finding the best practices in the industry. If you are a machine shop, or involved in metal fabrication, help us to define current, non-confidential, best practices for hazardous material and waste reduction.

Sign up for a Confidential Informational Interview

MnTAP Welcomes Gabrielle Martin

Gabrielle Martin joined MnTAP in early May as an Associate Engineer. Gabrielle has a Bachelor of Science in Materials Engineering from the University of Alabama at Birmingham. She has a background in ferrous and aluminum casting, automotive manufacturing, and construction sales. She is looking forward to leveraging her experiences to identify customer-oriented, environmentally and economically sustainable solutions for businesses around Minnesota.

Gabrielle Martin joined MnTAP in early May as an Associate Engineer. Gabrielle has a Bachelor of Science in Materials Engineering from the University of Alabama at Birmingham. She has a background in ferrous and aluminum casting, automotive manufacturing, and construction sales. She is looking forward to leveraging her experiences to identify customer-oriented, environmentally and economically sustainable solutions for businesses around Minnesota.

She is excited for the opportunity to put her Lean Six Sigma Green Belt training to good use. Gabrielle wants to get plugged in and give back to her new community of Minneapolis.

Gabrielle Martin – Associate Engineer

612-624-0206

gamartin@umn.edu

Salt Symposium – August 3 – 4, 2021

Fortin Consulting Inc. is organizing the Salt Symposium 2021. This live streamed symposium will shape the chloride conversation, presenting developments in salt use optimization for people and the environment. Presentation focus:

- Day 1 – New Directions in Chloride.

- Day 2 – Snow & Ice Management.

Keynote addresses and award presentations on both days.

Register Now!– registration per device, stream with colleagues

Symposium Agenda

2021 intern Symposium – Save The Date

August 18, 2021

The 2021 MnTAP Intern Symposium is scheduled for Wednesday, August 18, 2021 starting at 1:00pm. We anticipate a live streamed event as we had last year so that more guests can participate.

Registration will open later in June.