February 2024

Inside the Newsletter:

Cohort 6 | PFAS | Interns | Organics

Energy Efficiency Success in Minnesota Wastewater Treatment Plants

Since 2021, the Minnesota Technical Assistance Program (MnTAP) has been offering operator training focused on identifying and implementing low and no-cost improvements that reduce energy consumption at wastewater treatment plants (WWTPs), without sacrificing plant effectiveness at meeting discharge limits. The training is targeted at wastewater treatment plant operators at municipal mechanical treatment WWTPs. Operators receive 16 direct wastewater contact hours by completing this MPCA accredited course.

Since 2021, the Minnesota Technical Assistance Program (MnTAP) has been offering operator training focused on identifying and implementing low and no-cost improvements that reduce energy consumption at wastewater treatment plants (WWTPs), without sacrificing plant effectiveness at meeting discharge limits. The training is targeted at wastewater treatment plant operators at municipal mechanical treatment WWTPs. Operators receive 16 direct wastewater contact hours by completing this MPCA accredited course.

Operators in our most recent cohort, Cohort 7, were able to implement a total of $44,600 of annual savings with no-cost operational adjustments to their three plants. That’s an average of nearly $15,000 per plant!

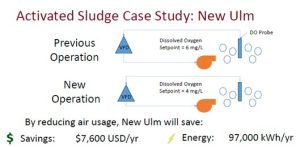

One inspiring case study was developed with our Cohort 7 participants from New Ulm. The New Ulm Wastewater Plant activated sludge process uses centrifugal blowers controlled by variable frequency drives (VFD) to provide sufficient air to meet an operator controlled dissolved oxygen concentration setpoint. The operators from New Ulm adjusted their dissolved oxygen setpoint from 6 mg/L to 4 mg/L and so far, have not observed any negative process impacts. This resulted in the average electricity consumption of the blowers decreasing by 97,000 kWh/yr of energy for an estimated savings of $7,600 per year.

Other no-cost operational changes our Cohort 7 operators successfully implemented included:

| Operational Changes | Implemented Savings (kWh/yr) | Implemented Savings (kW) | Implemented Cost Savings ($/yr) | Cost to Implement ($) |

|---|---|---|---|---|

| Operate Aerobic Digesters with 2 Instead of 3 Blowers | 141,500 | 28 | $11,200 | $0 |

| Reduce Oxidation Ditch Dissolved Oxygen From 7 to 2 mg/L | 97,000 | 11 | $7,600 | $0 |

| Reduce SNDR Foam Pump Speed From 100% to 78% in Winter Only | 34,100 | 7.8 | $1,400 | $0 |

| Reduce Aeration Basin Dissolved Oxygen Setpoint From 6 to 4 mg/L | 304,000 | 0 | $24,400 | $0 |

| TOTAL | 576,600 | 46.8 | $44,600 | $0 |

In total, MnTAP has conducted seven energy efficiency cohorts to date that have trained 39 WWTP operators. As a result, an annual 2,136,000 kWh of energy savings have been implemented at Minnesota WWTPs for an annual cost savings of $177,400.

If you are interested in participating in a local energy efficiency training with your nearby wastewater plants, please contact

Kira Peterson – Engineer

612-624-4653

kira@umn.edu

This project was funded through a grant from the Minnesota Department of Commerce.

PFAS Source Identification and Reduction Site Visits

MnTAP is executing a grant project funded by the United States Environmental Protection Agency (EPA) to address per- and polyfluoroalkyl substances (PFAS) source identification and reduction through 2025. We are currently scheduling site visits for Minnesota businesses. If you are interested in receiving technical assistance for identifying PFAS in your operations and exploring alternatives, please let us know!

You may be interested to know what a site visit will entail. To answer that question, we’ve developed the following summary:

First, we’ll begin with a call to understand a bit about your operations to try and understand the following questions: What are you making? Are there any target areas you’d like us to focus on? Have you done any sampling for PFAS, and if so, were there elevated results for chemicals with certain Chemical Abstracts Service (CAS) numbers that we could use to narrow our focus a bit?

From there, we’ll develop a game plan that will describe the areas of the operations that we’d like to tour. We’ll share what we’re looking for and ask some questions regarding the procedures in that space. We will use that information to guide our site visit which we anticipate to take 2-3 hours.

After the site visit, we will meet as a team and develop a list of data needs and identify topics for us to research. This part can be iterative as we are often piecing together incomplete information and trying to develop an understanding of where there might be PFAS in operations and whether there are replacement products to use instead.

Finally, we will provide you with a letter summarizing our findings and recommendations. This will include a recommendation regarding the need for any additional assistance. Following our letter, we will follow up with you within six months to see if there’s anything we can do to help facilitate the implementation of the recommendations. We will continue to follow up for two years with the intention of assisting with implementation and documenting successes.

For more information or to request a site visit, Contact

Kira Peterson – Engineer

612-624-4653

kira@umn.edu

Apply Now for the MnTAP Intern Program

The Minnesota Technical Assistance Program (MnTAP) is seeking junior or senior-level college students studying engineering or other science/technology disciplines to work on waste reduction, water conservation, and energy efficiency projects at companies in Minnesota this summer. MnTAP plans to support 15 intern projects during summer 2024 based at locations around the state, covering industries such as food processing and metal fabrication.

The Minnesota Technical Assistance Program (MnTAP) is seeking junior or senior-level college students studying engineering or other science/technology disciplines to work on waste reduction, water conservation, and energy efficiency projects at companies in Minnesota this summer. MnTAP plans to support 15 intern projects during summer 2024 based at locations around the state, covering industries such as food processing and metal fabrication.

Job descriptions for our 15 projects will each be posted as they are approved, but students only need to apply once and can do so right NOW! Visit our MnTAP Intern Program Students page to apply now and learn more.

For More Information, Contact

Matt Domski – Intern Program Manager

612-624-5119

mdomski@umn.edu

Organics: Recovery and Recycling

From feeding people to composting, there are many environmentally preferable options for diverting food and other organic waste from landfills and incinerators. Organic waste may include food waste, yard waste, paper products such as towels and napkins, and depending on jurisdiction, compostable ware. By reducing or diverting food and other organic wastes, you can reduce your environmental impact and avoid expensive disposal fees. Project Drawdown, an environmental non-profit out of San Francisco, ranks reducing food waste, specifically, as the #1 solution to limiting end-of-century warming to 2°C. It is crucial that organics are dealt with responsibly in any commercial setting.

Consider the following for reducing organics in your organization’s waste stream:

- Source Reduction – Reduce waste at the source.

- Feed People – Edible food waste can be donated to food banks and similar organizations.

- Feed Animals – Food waste can also be used to feed animals. In Minnesota, food-to-hog programs are popular.

- Industrial Uses – Various technologies exist that convert organics into high-value products such as soil amendments, pelletized fuel, and biogas.

- Composting – Food and other organic waste can be recycled into compost. Food can be mixed with other organic materials, such as compostable plastics and paper products, and sent to a composting facility.

Visit our webpage on Organics: Recovery and Recycling to learn more! If you’re looking for assistance call MnTAP to investigate ways to reduce, reuse, and recycle your food and other organic wastes at your site.

Additional Resources

- Feeding Food Processing By-products to Livestock (MnTAP)

- Food-to-Livestock Options (MnTAP)

- Compost – Approved/Qualified Products – MnDOT (state.mn.us)

- Minnesota: ReFED | Rethink Food Waste

For More Information, Contact:

Jon Schroeder, LEED AP – Sustainable Materials Management Specialist & Minnesota Materials Exchange Administrator

612-624-4645

jschro@umn.edu