July 2019 – Symposium and 35th Anniversary Celebration

Inside the Newsletter:

MnTAP’s Anniversary & Symposium | MnTAP’s Legacy | Intern Program | 1st Intern Project | TCE | State Fair EcoExperience

MnTAP 35th Anniversary Celebration and Intern Symposium

You are invited to a reception celebrating the Minnesota Technical Assistance Program’s 35th Anniversary on Wednesday, August 21, 2019, from 12:00 noon to 1:00pm at the McNamara Alumni Center on the University of Minnesota campus. We welcome our partners, companies, and other guests to join us in celebrating past successes and looking ahead to the future.

The 2019 MnTAP Intern Symposium will be held immediately following the 35th Anniversary Celebration on Wednesday, August 21, from 1:00 – 4:30 p.m. The event includes intern presentations, poster sessions and breaks that will provide opportunities to network and interact with the interns.

RegisterLearn how sixteen MnTAP interns spent their summer helping companies save money and improve the environment with water conservation, pollution prevention, and energy efficiency projects.

- Find out how many water efficiency opportunities Sam, Heather, Sayandeep, Noah, Erin, Larry, and Nick identified at their sites?

- What were some of the unexpected sources of air emissions Melody and Elizabeth identified at small businesses?

- Where did Patrick, Josh, Bailey, and Josiah find energy savings this summer?

- What were some of the solutions Amit, Christopher and Josh found to reduce hazardous waste at their sites?

Both events will take place at the McNamara Alumni Center on the University of Minnesota East Bank Campus. For more information about the intern program, visit MnTAP’s Intern Page or contact Matt Domski at 612-624-5119 or 800-247-0015.

More InformationA Legacy of Minnesota Technical Assistance Built over 35 Years

35 years ago the Minnesota Technical Assistance Program (MnTAP) was established as part of the University of Minnesota, School of Public Health to help the State of Minnesota provide waste reduction technical assistance As part of the University of Minnesota, MnTAP is able to engage businesses and organizations, build trusted relationships and provide valuable service to help businesses improve their operating performance and the State meet pollution prevention goals.

MnTAP was founded at a time when people started realizing the serious ecological and public health impacts of unchecked pollution and took action to decrease emissions to our air, water and land. These actions helped reclaim drinkable, fishable waters, improved air emissions to the point where poor air quality days are decreasing and developed the framework where proper management of hazardous waste is an expectation of doing business. MnTAP is proud to continue to be part of the ongoing opportunity for improvement offered by source reduction activities. Source reduction activities seek to improve efficient use of resources by using less hazardous materials to minimize the risk of employee and public exposure, decreasing air pollution so incidents of childhood asthma cannot be predicted by residential zip codes and offering strategies to maximize efficient use of our water supplies and treatment systems.

Since 1984 MnTAP staff members have been dedicated to providing high quality, no-cost technical assistance to businesses of all sizes throughout Minnesota. The past and present MnTAP staff members have completed 5,000 site visits to facilities across the State of Minnesota and have impacted countless more through success stories and case studies. This effort has resulted in

- 400 million pounds of hazardous and solid waste not created, handled or managed

- 800 million gallons of water not pumped, treated or discharged

- $53 million in first year cost savings for facilities working with MnTAP.

Facilities that have taken advantage of MnTAP services and implemented recommendations provided for them have reaped great rewards in terms of preventing pollution, reducing waste, conserving energy, and saving money.

Over the past 35 years, MnTAP has created a legacy of quality technical assistance for Minnesota businesses that ranks among the best in the country in providing pollution prevention and technical assistance support. With this solid foundation behind us, we look forward to providing value added assistance for Minnesota businesses over the next 35 years.

MnTAP Intern Program, an Important Part of the Legacy

The MnTAP Intern Program has provided nearly 300 students with site based projects that prepare them to be the next generation of engineering leaders. Businesses gain extra resources to address opportunities to improve resource utilization and operating cost and Minnesota realizes significant, positive environmental outcomes.

The MnTAP Intern Program has provided nearly 300 students with site based projects that prepare them to be the next generation of engineering leaders. Businesses gain extra resources to address opportunities to improve resource utilization and operating cost and Minnesota realizes significant, positive environmental outcomes.

The MnTAP Intern Program began in 1985 and is one of the longest-running pollution prevention intern programs in the country. From the start, MnTAP interns were making suggestions that improve operational efficiency, save money, reduce waste, or decrease regulatory compliance burden. They have the time and creativity to research alternative equipment, procedures, chemicals, and raw materials. Additionally, they create a full report detailing the intern’s work and next steps for the company to use into the future.

MnTAP’s first intern was hired in 1985 to work with Midwest Finishing, Inc., at their former site in Coon Rapids. Midwest Finishing, Inc. specializes in electroplating microcomponents and metal finishing for both standard and precious metals. The intern studied the process and recommended a process solution that would reduce of as much as 90% of the hazardous components in the site wastewater sludge.

Not bad for the first intern project!

First MnTAP Intern Project – 1985

Midwest Finishing in Coon Rapids believes that having a MnTAP student intern dedicated to their waste reduction project “moved up the timetable for evaluating, selecting, and installing equipment for metals recovery from their plating wastewater streams.” Midwest Finishing is a precious metal plater of gold and silver. The spent rinse-waters are sent-offsite for recovery, but copper and other metal rinse-waters have historically been pre-treated on-site, then discharged to the sewer system. The company uses an existing system for neutralization, precipitation of metals, and sludge de-watering as pre-treatment prior to sewer discharge. However, in order to expand operations, and meet sewer discharge requirements, Midwest Finishing needed to install a metals recovery system to remove metals from its waste waters.

The MnTAP intern program assisted in the evaluation of equipment that would produce a “cleaner” waste stream that could enter the firm’s final pre-treatment system.

After reviewing technical literature and talking with vendors, Midwest Finishing selected an electrolytic metal recover (EMR) system, in conjunction with the existing pre-treatment system. It is estimated that the installation of the new metals recovery system will result in a reduction of as much as 90% of the hazardous components of the sludge.

Don’t Make the Wrong Switch!

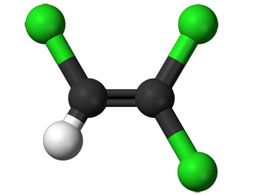

The Minnesota Technical Assistance Program (MnTAP) at the University of Minnesota and the Toxic Use Reduction Institute (TURI) at the University of Massachusetts, Lowell are partnering to provide no cost, technical assistance to find effective, safer cleaning options than trichloroethylene (TCE) for Minnesota businesses.

On June 11, 2019 MnTAP and partner TURI offered a training session on finding effective alternatives to TCE and more information about the TCE Alternatives Project. Recordings of the event are now available for review on the MnTAP website.

RecordingsGoing to the State Fair? Don’t Miss the ECO Experience

August 22 – September 2, 9:00 AM – 9:00 PM daily

August 22 – September 2, 9:00 AM – 9:00 PM daily

The Eco Experience is a huge exhibit at the Minnesota State Fair, filled with hands-on activities, demonstrations and, resources. Interact with the new exhibits which highlight the latest in easy, everyday reduce-reuse-recycle how-tos, healthy cooking, innovations in green technology and transportation, and other compelling topics on environmentally focused living.