March 2019 – Celebrating 35 Years of Pollution Prevention

Inside the Newsletter:

Introducing E-Source | MnTAP Celebrates 35 Years | Impact | North Minneapolis Air Reduction | Two Celebrations | Blast From the Past | PCA Grants

Introducing E-Source

Welcome to our new newsletter. We have combined our printed newsletter –Source – and our monthly e-newsletter into one informative online newsletter focused on strategies to help Minnesota businesses, reduce waste, and save money. In doing this, we are following our own advice and reducing the amount of paper products we use and send to our readers.

We will reduce our annual environmental impact per year by approximately:

- 300 lbs CO2

- 9,000 gallons of water

- 1,000 lbs solid waste

Some readers may not know the reason why we call our newsletter “Source.” MnTAP’s mission is to help prevent pollution at its “Source” through source reduction and technical assistance. In addition, we want to be a source and resource of information and assistance to the people and businesses of Minnesota.

Remember that of the 3-Rs, reduce, reuse and recycle, reduce is best!

Please feel free to send any comments or suggestions to us so we can send you information that is valuable to you.

MnTAP Celebrates 35 years of Pollution Prevention Assistance

Throughout 2019, MnTAP will celebrate 35 years of providing pollution prevention, energy and water efficiency assistance to Minnesota’s businesses. Over time, businesses working with MnTAP’s scientists and engineers have recorded significant cost savings. In fact, those companies have saved over $53.2 million while reducing 199,000 tons of waste, 790 million gallons of water, 77.1 million kWh, and 5.5 million therms.

MnTAP’s mission of providing waste reduction technical assistance was set forth by the Minnesota legislature who enacted the Minnesota Waste Management Act (Section 115A.152) in 1984. Then, in 1990, the Minnesota Toxic Pollution Prevention Act (Minn. Stat., Chapter 115D) was signed into law and MnTAP began offering pollution prevention assistance.

Since 1984, MnTAP staff members have completed over 4,725 site visits to facilities across the State of Minnesota. These visits have allowed staff members to not only learn about processes at each facility, but also to build relationships with facility staff that have reaped great rewards for both the company and Minnesota. MnTAP has developed in-depth knowledge about manufacturing processes and implemented successful strategies for preventing pollution and conserving energy and water for Minnesota businesses and make recommendations for process improvement.

The MnTAP intern program is one of the longest running intern programs in the country. Over the years, MnTAP has hired 278 students who have worked to develop and recommend solutions to some of the most pressing pollution prevention and energy efficiency questions. Businesses have successfully implemented solutions that have saved them millions of dollars. Through this program, interns have gained real-world experience. MnTAP staff members connect with more facilities throughout the state.

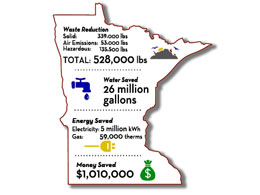

Our Impact on Minnesota in 2018

Every year, MnTAP calculates the environmental and economic impact of our pollution prevention and process efficiency work with Minnesota businesses. Through funding from the Minnesota Pollution Control Agency (MPCA), as well as other partners, MnTAP’s 11 staff members are able to focus on providing cost-saving solutions to businesses in three ways:

Every year, MnTAP calculates the environmental and economic impact of our pollution prevention and process efficiency work with Minnesota businesses. Through funding from the Minnesota Pollution Control Agency (MPCA), as well as other partners, MnTAP’s 11 staff members are able to focus on providing cost-saving solutions to businesses in three ways:

- On-Site Assistance

- Intern Program

- Materials Exchange

MnTAP staff members spent considerable time in 2018 with 110 on-site visits at a variety of facilities. These one-on-one site visits are a key strategy that MnTAP uses to develop solutions that are appropriate for each facility and to build relationships with employees. When on-site, MnTAP staff members gain a better understanding of the processes in place and are better able to identify strategies for improving efficiency and reducing waste and energy use. MnTAP staff were able to find and the facilities implemented:

- 120 MnTAP recommended process changes

- reductions nearly 26.3 million gallons of water

- 528,000 pounds of waste,

- 5.1 million kWh

- 59,000 therms of energy.

- Combined, these reductions are saving companies $1,010,000 annually.

A good example of the types of savings our staff and interns recommended this year was seen at Carley Foundry. Carley found that by simply using overnight setback temperatures (1,400F to 1,280F) for their molten metal, they would save over 2 million kWh and $104,000 annually.

In 2018, companies that used the Materials Exchange program were able to prevent 53,000 lbs thousands of pounds of solid material from landing in a landfill. Materials exchange is utilized by various organizations as a business to business exchange of usable goods to save money and avoid waste.

Read MnTAP’s full environmental benefits report, which highlights special projects and the organization’s overall achievements.

North Minneapolis Sees Air Emission Reduction

MnTAP worked with the University’s Urban Research and Outreach-Engagement Center (UROC) located in North Minneapolis, and other community partners, to assist commercial and industrial businesses in North Minneapolis. The goal was to help reduce air emissions through adoption of less toxic, lower-emission, alternative degreasing solvents. Decreasing these emissions not only cuts down on the area’s air pollution, but provides a much healthier work place for employees.

MnTAP worked with the University’s Urban Research and Outreach-Engagement Center (UROC) located in North Minneapolis, and other community partners, to assist commercial and industrial businesses in North Minneapolis. The goal was to help reduce air emissions through adoption of less toxic, lower-emission, alternative degreasing solvents. Decreasing these emissions not only cuts down on the area’s air pollution, but provides a much healthier work place for employees.

After identifying the types of degreasing products and their components, MnTAP worked directly with 17 companies to provide free technical assistance and product samples to encourage the adoption of alternative, safer, products.

During the project, MnTAP also gathered information about motivations and barriers that influence the adoption of safer alternatives. To date, including reduction of 105 lbs of volatile organic compounds (VOCs), 155 lbs of hazardous air pollutants (HAPs), and 2,700 lbs of solid waste. The results will be shared with the entire community at the end of the project.

Two Celebrations in One!

MnTAP will be including a 35th anniversary celebration with our 2019 Intern Symposium on August 21. We welcome our partners, companies, and other guests to join us in celebrating our successes and looking ahead to the future. For more information, please contact MnTAP at 612 – 624 – 1300.

A Blast from the Past

Get plugged in to financial assistance

In 2009, MnTAP conducted a survey of approximately 450 manufacturers and other interested parties in Minnesota.

In that survey, respondents indicated that the lack of available financial resources was the most significant barrier to implementing pollution prevention and energy efficiency projects.

To help you find financing opportunities, MnTAP has a listing of resources available on our Financial Assistance page. Grants, loans, and utility rebates may help your company obtain the financing needed to implement a cost-saving pollution prevention or energy efficiency project.

PCA Grants for Wood and Metal Finishing Operations — due April 8

MPCA grants are now open for small businesses and organizations across Minnesota to switch to alternative wood, wood composite, or metal finishing products.

The maximum award is $15,000 with a 50% minimum match. Additional preference will be given to projects located in areas of concern for environmental justice, small businesses and organizations, and small organizations that are veteran-owned, economically disadvantaged, or a targeted-group business based on ownership.

In order to be eligible, finishing operations must be integral to the manufacturing of final salable products and you must be either:

- A for-profit business located in Minnesota with under 500 employees

- A governmental entity, educational institution, or non-profit organization within Minnesota with any number of employees