May/June 2019 – Waste Water Optimization

Inside the Newsletter:

Energy Efficiency Implementation | Driving Wastewater Efficiency | Webinar | Wastewater Nutrient Removal | Pharmaceutical Wastes | Dry Cleaning Outreach | SAVE the DATE!

Energy Efficiency Implementation in Minnesota Wastewater Treatment Facilities

Delivering wastewater treatment services to communities can be a high cost effort due to the energy intensity of the operating equipment and the need to meet increasing effluent quality requirements for positive public health and environmental outcomes. Across the U.S., the water and wastewater treatment sectors account for 3% of total electricity use.

Cities are under constant pressure to deliver improved services and at the same time manage operating costs. Energy is a large component of facility operating cost accounting for 25-40% of the operating budgets of most wastewater utilities. U.S. EPA lists numerous benefits of improving energy efficiency such as reducing energy cost, reducing air pollution and GHG emissions, improving energy and water security, supporting economic growth, and protecting public health. Improving wastewater treatment energy efficiency can help cities and businesses improve operating cost and environmental outcomes.

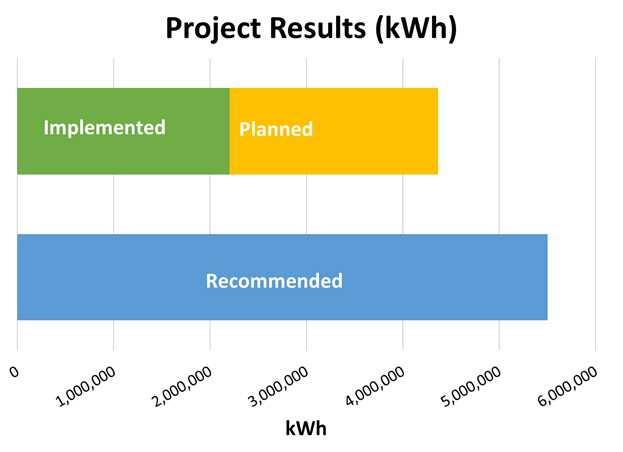

The primary goals of this project were to decrease energy use in Minnesota municipal wastewater facilities and scope opportunities for renewable energy generation at suitable facilities. To accomplish this goal the Minnesota Department of Commerce (Commerce), MnTAP, and the Minnesota Pollution Control Agency (MPCA) collaborated to provide technical assistance to selected wastewater treatment plants (WWTPs) and identify significant energy savings through improved efficiency as seen in the chart below.

Read MoreAcknowledgement: The information, data, and work presented herein was funded in part by the Office of Energy Efficiency and Renewable Energy, U.S. Department of Energy, under Award Number DE- EE0006888.

Driving Wastewater Treatment Energy Efficiency: A Cohort Training and Implementation Plan

This project was aimed at water, energy and GHG emissions reductions for the Lamb Weston facility in Park Rapids. The intern helped evaluate the potato blanching process for potential improvements in the efficiency of water, chemical and energy usage to align with the facilities sustainability goals.

This project was aimed at water, energy and GHG emissions reductions for the Lamb Weston facility in Park Rapids. The intern helped evaluate the potato blanching process for potential improvements in the efficiency of water, chemical and energy usage to align with the facilities sustainability goals.

The MnTAP intern made a simple and cost-effective procedural change to increase the plant’s chemical usage efficiency. The intern focused on optimizing the rate and duration of the application spray time of sanitizing chemical used in foot baths located at 10 entryways to the production floor. This reduced the amount of chemicals being purchased and used, as well as the time spent mixing and delivering the materials to the stations. The modifications resulted in a reduction of 5,000 lbs of chemical, 3,200 gallons of water, and $11,000 in savings every year.

At a separate food manufacturer, it was discovered that by changing the type of floor mats used throughout the facility, the amount of sanitizing chemical used to fill the mats could be reduced by up to 40%. The surface of the mats consisted of densely packed cylindrical nubs designed to dislodge and scrape away soils from footwear. However, because the facility was filling these mats with a powder chemical rather than liquid, a significant amount was lost in the void spaces between the nubs and could not make effective contact with employees’ footwear. It is estimated that switching to mats with flat treads would allow the company to use 600 lbs less sanitizing powder yearly – a savings value of $3,800.

Utility Webinar: A Cohort Approach to Wastewater Treatment Energy Efficiency

Learn about how to effectively achieve significant energy savings in mechanical wastewater treatment plants

Tuesday, June 25, 2019, 11:00 a.m. -12:00 p.m.

Mechanical wastewater plants use large, industrial blowers to facilitate treatment of water throughout the state. The cohort approach to wastewater treatment energy efficiency draws on research to develop a program approach for Minnesota’s wastewater treatment sector through delivering tailored training while leveraging peer networks to effectively achieve wastewater treatment plant energy efficiency.

This webinar will explain how this approach may be used as a utility CIP program, including program administration considerations as a result of the geographic distribution of mechanical wastewater plants to achieve statewide energy savings. The webinar will also highlight the mechanics of the training program, as well as its methods to help wastewater operators identify and implement operational energy efficiency opportunities.

The webinar will be co-led by Audrey Partridge and Julie Drennen with the Center for Energy and the Environment and Jon Vanyo with MnTAP. Partridge and Drennen are regulatory policy experts who will describe the CIP model strategy in depth. Vanyo is an engineer with five years of experience on projects related to wastewater energy efficiency and nutrient optimization; he will explain the training and implementation portion of the program.

This project was supported by a grant from the Minnesota Department of Commerce, Division of Energy Resources, through the Conservation Applied Research and Development (CARD) program, which is funded by Minnesota ratepayers.

Wastewater Nutrient Removal Optimization

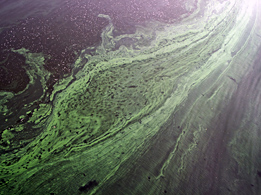

The goal of this project is to optimization nutrient removal (nitrogen and phosphorus) at mechanical wastewater plants and pond systems. Reduction of nutrients from facility effluent streams helps facilities meet increasingly stringent effluent limits designed to protect surface water keeping it safe for downstream uses and recreation.

The goal of this project is to optimization nutrient removal (nitrogen and phosphorus) at mechanical wastewater plants and pond systems. Reduction of nutrients from facility effluent streams helps facilities meet increasingly stringent effluent limits designed to protect surface water keeping it safe for downstream uses and recreation.

The project team is in the process of working with three mechanical plants on nutrient optimization strategies. The team collects information on facility operations, and models the flow and nutrient removal rates throughout the treatment process. By adjusting parameters such as oxygen levels and re-circulation rates within the model, the project team can develop operational strategies that maximize nitrogen and phosphorus removal for trialing by plant staff.

The project is using the same process to research wastewater treatment ponds.

The team has observed high oxygen levels in tanks that are supposed to be anaerobic which may impede phosphorus removal, while lack of re-circulation from an aerobic to an anoxic zone can limit denitrification efficiency.

If you are interested in learning more about the project or participating, contact Jon Vanyo at vanyo@umn.edu or 612–624–4683.

Acknowledgement: The authors would like to acknowledge support for this project by the Minnesota Pollution Control Agency (MPCA) with funding provided by the Minnesota Environmental and Natural Resources Trust Fund as recommended by the Legislative-Citizen Commission on Minnesota Resources (LCCMR). The Trust Fund is a permanent fund constitutionally established by the citizens of Minnesota to assist in the protection, conservation, preservation, and enhancement of the state’s air, water, land, fish, wildlife, and other natural resources. Currently 40% of net Minnesota State Lottery proceeds are dedicated to growing the Trust Fund and ensuring future benefits for Minnesota’s environment and natural resources.

Pharmaceutical Wastes: New Requirements and Allowances

Effective August 22, 2019, healthcare facilities, including nursing homes, may no longer sewer any pharmaceutical wastes that are federal hazardous wastes. Group homes with a capacity of six residents or less are exempt from this ban. Controlled substances will no longer be regulated as hazardous wastes, but must continue to meet all U.S. Drug Enforcement Administration (DEA) requirements. Over-the-counter nicotine replacement therapy products approved by the U.S. Food & Drug Administration (FDA) will also no longer be regulated as hazardous wastes. Prescription and recreational nicotine products will remain fully regulated as hazardous wastes when disposed.

Starting in 2022, the MPCA anticipates that all pharmaceutical wastes, including state-specific hazardous wastes, from any business will be banned from sewering.

The MPCA will be publishing more detailed information on these changes as soon as possible on its Hazardous Waste Publications webpage.

The EPA presented a webinar about the contents of the final rule on April 2, 2019 and a recording of that webinar is now available. Click the “View Archive” button on the webinar web page to access the recording. Additionally, the presentation slides from the webinar can be found in the “Webinar Slides” tab on this same page.

More InformationReprinted from the Small Business Enterprise (MPCA) Spring newsletter.

Dry Cleaning Outreach

Did you know that utility costs can be up to 25% of your dry cleaner’s annual operating expenses? The Minnesota Technical Assistance Program is offering free technical assessments to Minnesota dry cleaners to find ways to save money on energy, water and chemical use. Assessments take 30 minutes to an hour and are confidential and non-regulatory. MnTAP staff will follow up the assessment with a report that details recommendations to save money and reduce waste and includes resources to help your business at low or no cost.

Did you know that utility costs can be up to 25% of your dry cleaner’s annual operating expenses? The Minnesota Technical Assistance Program is offering free technical assessments to Minnesota dry cleaners to find ways to save money on energy, water and chemical use. Assessments take 30 minutes to an hour and are confidential and non-regulatory. MnTAP staff will follow up the assessment with a report that details recommendations to save money and reduce waste and includes resources to help your business at low or no cost.

Services include:

- Energy use assessment

- Water usage assessment

- Leak checks on dry cleaning machines

- Tailored recommendations

- Follow-up and implementation assistance

Interested? Call Nathan Landwehr at 612 624-4697 or email at landwehr@umn.edu to learn more about the project and set up an assessment today.

SAVE the DATE! MnTAP Intern Symposium and 35th Anniversary Celebration

Since 1984, MnTAP has helped businesses reduce waste and lower their energy and water use, while reducing their process costs. On Wednesday, August 21st MnTAP will be combining the annual Intern Symposium with an anniversary celebration. Join us as we celebrate MnTAP’s legacy of reducing waste at the source to improve public health and the environment. We will look ahead to the future to learn about the recommendations our 2019 cohort of interns have identified that will have positive impacts on Minnesota businesses environmental footprint and profitability.

Since 1984, MnTAP has helped businesses reduce waste and lower their energy and water use, while reducing their process costs. On Wednesday, August 21st MnTAP will be combining the annual Intern Symposium with an anniversary celebration. Join us as we celebrate MnTAP’s legacy of reducing waste at the source to improve public health and the environment. We will look ahead to the future to learn about the recommendations our 2019 cohort of interns have identified that will have positive impacts on Minnesota businesses environmental footprint and profitability.

For more information, please contact MnTAP at 612-624-1300, mntap@umn.edu, or find out about previous symposiums on the Intern Symposium page.