June 2025

Inside the Newsletter:

Intern Interview | IMPACT 2024 | Reducing Energy Use | Events | Funding Opportunities

Q&A with a Former MnTAP Intern: Denzel Bibbs

The MnTAP Intern Program recruits undergraduate and graduate students interested in building first-hand experience and practical expertise on water conservation, energy efficiency, pollution prevention, and sustainable chemical solutions. These interns spend up to 500 hours working for host facilities in a variety of sectors – such as government, health care systems, metal finishing, food processing, and other manufacturing— with guidance from a MnTAP engineer or scientist and an on-site supervisor. At the end of the summer, MnTAP interns produce recommendations that are presented to company staff, compiled in a comprehensive report, presented to the public at the MnTAP Symposium, and written up in a two-page summary published in Solutions.

The MnTAP Intern Program recruits undergraduate and graduate students interested in building first-hand experience and practical expertise on water conservation, energy efficiency, pollution prevention, and sustainable chemical solutions. These interns spend up to 500 hours working for host facilities in a variety of sectors – such as government, health care systems, metal finishing, food processing, and other manufacturing— with guidance from a MnTAP engineer or scientist and an on-site supervisor. At the end of the summer, MnTAP interns produce recommendations that are presented to company staff, compiled in a comprehensive report, presented to the public at the MnTAP Symposium, and written up in a two-page summary published in Solutions.

Since the intern program began in 1985, 367 students have completed their internships. Recently, we caught up with some former MnTAP interns and learned more about where they are now. Our third intern interview was with Denzel Bibbs, who currently is a Project Engineer at Findorff working in construction management.

In this Q&A, we connect with Denzel to talk about his current work, his 2017 MnTAP internship at Kerry Group, what he took away from that experience, and how other companies can benefit from MnTAP interns. This interview has been edited and condensed for clarity.

Could you briefly describe your current role?

Here at Findorff, I’m in the project management department. I am currently on-site full-time at a construction project. The project is the Center for Black Excellence and Culture on the south side of Madison, Wisconsin. It’s a brand new 44,000 square feet building and community space. My role there is to oversee some of the day-to-day logistics of the project, such as material ordering, scheduling, coordinating with subcontractors, and working with people in the field who carry out the installations. At Findorff, we have self-perform construction trades, like concrete, steel, and masonry. So, for me, it’s really getting to know how those in the field do their work with resources that they need and how to best support them. I keep the information flowing so they can continue to do their work.

Thinking back on your MnTAP projects, could you briefly describe what you worked on?

As an MnTAP intern, I worked at Kerry Group, which is a food processing plant in Rochester, Minnesota. What I worked on was analyzing some of their key systems within the food production facility to see if there were any opportunities for gains in efficiency and conservation. I focused on analyzing their energy use. They used a gas boiler for producing steam, and that steam generates some of the heat used for food processing activities. They also had a caustic dosing system for wastewater, which was used to keep pH within a certain range prior to sending that water back through the city sewer. To maintain that pH level, I did some analysis on how often they are conducting caustic or acidic dosing to manage their effluent pH levels, and if there were any benefits to having an agitation system in a bulk tank prior to sending that wastewater out.

I then carried out energy analysis on how much energy was needed to pump water from the well throughout the facility. They used well water for cooling purposes, and the pump that they were using was not on a variable frequency drive (VFD). I did some analysis to see what the potential electric and water savings would be if they switched to a VFD.

I also looked at some of the steam waste within the food production facility. Once they use the steam for heating, condensate water from that steam goes through a return system. Some of the valves were not functioning, and I explored replacing those valves to better capture more of the return water back to the boiler.

What skills did you learn or hone while working on your MnTAP project?

One of the main skills I acquired as a MnTAP intern was settling into a project team. It was one of my first opportunities to really work with the company and with full-time professionals. This means communicating with full-time professionals and sitting in on meetings.

Because the food production facility was undergoing expansion, I actually showed up to a job site trailer every day. They didn’t have enough room for all their office staff. Having to work at an office out of a job site trailer and then walk through the production facility or factory floor to see what kind of activity is taking place is actually very similar to what I do now in the construction field. Right now, I work out of an office trailer and walk to the site every day.

Another skill I learned was being analytical, which includes looking at a problem for opportunities and communicating them in ways that would make the most sense for the client. I do the same sort of things today, like cost-benefit analysis of construction materials or alternative installation methods. I continue to communicate with the Findorff construction team members and work with that team to communicate to our clients.

Can you talk a little more about how the MnTAP internship helped you learn to communicate better in a professional setting?

My MnTAP internship helped me improve my communication skills, even for simple things. Students may not have the opportunity to sit in on meetings and in professional settings. There is a cadence to how a meeting works at a typical company, especially in a firm that’s centered on engineering, science, or technology. There are professional norms on what to communicate over email versus phone in a professional setting. We need to build an understanding of which communication method is appropriate and would be the most effective for the issue at hand. The MnTAP internship allowed me to go through more repetitions of that in determining which method of communication to use along with practicing how to initiate communications.

My experience with folks at Kerry is that they were very supportive of my learning experience, but they didn’t hold my hand the whole time. They gave me space to initiate those conversations and ask those questions when I was walking the factory floor. I learned to be comfortable with asking questions to people I didn’t know yet, and these questions included, “Hey, what is this process you’re doing?”, or “What are you working on?” Today, I’m constantly asking similar questions in the field like, “Why are you installing those windows with that method?”, or “Can you tell me more about the installation you’re doing?” So, my MnTAP internship definitely helped me develop that curiosity and knowledge on how to ask questions.

What, if any, values or commitments do you still practice from your MnTAP internship?

In construction, most of our efforts focus on reducing material and reducing rework. MnTAP taught me to be resourceful by providing or referring me to online tools, like tools from the Department of Energy, and other software. I learned how to be resourceful on the internet. That was key to my learning because many of these resources are technical in nature.

I continue to do research in my construction work now. There are a lot of standard books and technical resources that I use, such as installation methods for me to stay ahead of the work and ensure that the construction can be as efficient as possible. The more efficient and well-planned the construction process is, the lower the chance that we will need to do rework or produce waste. If we can catch that early, then the project will be more efficient as a whole.

I also continue to communicate these new initiatives to staff in the field and with our clients. Often times, we may find an alternative that is more sustainable and could be of value to the client. So, learning how to communicate the sustainability benefits of that new material or different installation method. Articulating what the gains are— whether that’s CO2 reduction or less material going into the landfill—and quantifying those reductions when we communicate.

How did participating in a MnTAP internship shape your understanding of what kind of career you eventually pursued?

The MnTAP experience gave me a lot of project management skills when my college experience didn’t necessarily teach me that project management could be a direct career path that was available to engineers. For a lot of students, including myself, I always thought that the engineering track was going to be heavily design and technical based. Whereas right now, my career is very project management based with a background in technical knowledge of construction.

And that is similar to the MnTAP internship for me in the sense that I wasn’t designing the VFD to reduce electric use. I was managing the information gathering to make the determination of whether the VFD would be a good opportunity to pursue.

In summary, the MnTAP internship was a great experience in the field and taught me to take initiative, be self-reliant when walking around a facility to gather information, and to understand the technical ramifications of the information gathered. In my current work in construction, I’m not necessarily designing, but I’m managing aspects of the project in which I need to understand the technical information. The MnTAP internship helped me understand that this workflow is something that I can do full time.

Given your experiences, how would hiring an MnTAP intern benefit your team or other professionals working in your area?

I’ll speak to the construction industry. I think the MnTAP program would be great for construction firms, especially general contractors, that are looking to bring added value either to the general contractor itself or even the client that the general contractor is serving. For us at Findorff, we have an in-house sustainability lead. We often spearhead sustainability initiatives with their clients because it’s something that clients are also passionate about. I can foresee us benefiting from having a MnTAP intern be our dedicated person working on sustainability, whether it is in the construction process itself, in designing the building, or working hand-in-hand with one of our clients.

Conclusion

If you are a student interested in an experience like Denzel’s or are a company/organization interested in gaining the help and expertise of a MnTAP Intern, learn more about the program. MnTAP interns gain practical, on-the-job training while making a difference. Host facilities benefit from recommendations that have led them to save money; reduce waste or use of water, energy, and chemicals; and become overall more environmentally sustainable.

This program is also accessible for smaller to medium-sized businesses with an affordable cost share (i.e., $4,000) and realistic expectations to host an intern (e.g., 3 to 5 hours of supervision for the first 2 to 3 weeks of onboarding that typically drops down to 1 to 3 hours per week for the rest of the project). For questions on all aspects of the MnTAP Intern Program, please email or call Matt Domski at mdomski@umn.edu or (612) 624-5119.

Author

Jocelyn Leung- Communications Specialist

Contact:

Matt Domski – Intern Program Manager

mdomski@umn.edu

612-624-5119

MnTAP Releases 2024 IMPACT Report

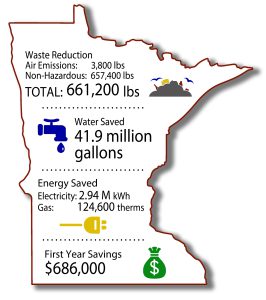

In 2024, the Minnesota Technical Assistance Program (MnTAP) marked a major milestone—40 years of helping Minnesota businesses reduce waste, conserve resources, and improve efficiency. This year’s results, captured in the 2024 IMPACT Report, reflect the long-standing dedication of MnTAP and the strength of our partnerships across the state.

In 2024, the Minnesota Technical Assistance Program (MnTAP) marked a major milestone—40 years of helping Minnesota businesses reduce waste, conserve resources, and improve efficiency. This year’s results, captured in the 2024 IMPACT Report, reflect the long-standing dedication of MnTAP and the strength of our partnerships across the state.

2024 Highlights:

- 41.9 million gallons of water conserved

- 2.9 million kilowatt-hours (kWh) of electricity saved

- 124,600 therms of fuel reduced

- 661,200 pounds of waste eliminated

- $686,000 in annual cost savings realized

In 2024, MnTAP provided technical assistance to 318 organizations, including 65 in areas identified as having environmental justice concerns. Our team also conducted 177 site visits and supported 14 student intern projects. While this work broadly focused on our main topics of water conservation, energy efficiency, and pollution prevention, our data showed that energy efficiency was the top reason our clients reached out to us.

MnTAP’s work in 2024 also included targeted efforts to reduce pollutants such as per- and polyfluoroalkyl substances (PFAS), volatile organic compounds (VOCs), and hazardous air pollutants while addressing climate impacts from food waste and promoting sustainable practices across sectors.

We remain committed to supporting Minnesota’s businesses and communities in meeting today’s environmental challenges through practical, cost-effective solutions. I hope you enjoy reading this year’s Impact publication and join me in thanking our team for all their great work in making the State of Minnesota a healthy, safe place to live.

Contact

Kelsey Klucas – Director

kluc0035@umn.edu

612-624-4619

Framework for Reducing Energy Use in Business Operations [Part 2]

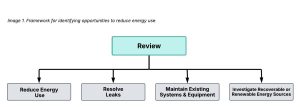

Making changes to conserve energy can lead to lower bills, maintain or improve productivity, and protect the environment. This month’s article elaborates on an energy efficiency framework for manufacturers built from strategies proposed by MnTAP interns over the past five years. Most of these interns’ strategies fell into the following five general categories:

- Review or audit how much energy is currently used and where it is being used.

- Reduce energy use in current operations through new equipment and optimal procedures.

- Resolve leaks of heated air, steam, cooled air, and compressed air.

- Maintain existing systems so they can operate at peak energy efficiency.

- Investigate recoverable energy (i.e., energy currently wasted or lost) or renewable energy opportunities onsite. These may help companies reduce their dependence on the electrical grid, which can be expensive and unpredictable.

Image 1 illustrates how the review category is the starting point that can lead into the other four categories.

Last month’s article went over how to review and reduce energy use. This month’s article will cover how to resolve leaks, maintain existing systems and equipment, and investigate recoverable or renewable energy sources.

Resolve Leaks

Many of the tests covered in the reviewing category are responsible for identifying loss of energy through leaks. It is energy intensive and expensive to produce compressed air, cooled air, heated air, and steam. Therefore, resolving the associated leaks offer large savings opportunities, and MnTAP interns have come up with many recommendations on how facilities can improve their sealing and insulation to minimize energy loss and associated costs from leaks.

Sealing

Sealing is eliminating the leak of energy through unwanted air exchange. Since so many MnTAP interns have touched on compressed air specifically, it is worth discussing compressed air sealing recommendations as their own group.

Compressed air systems are ubiquitous within industry and around 70% of manufacturers use them. Compressed air is one of the most significant uses of energy in a facility, and up to 30% of a compressor’s yield may be lost in leaks. In addition, poorly operating compressed air systems can lead to drops in system pressure or reduce pneumatic equipment’s efficiency.

One reason why MnTAP interns focus on compressed air is because recommendations are often inexpensive and have a quick payback period. Some of the most common strategies for addressing compressed air leaks are:

- Seal existing compressed air leaks (e.g., those occurring in pneumatic systems) or repair broken equipment (e.g., valves) that contribute to those leaks. From these audits, MnTAP interns could pinpoint areas that are more prone to developing leaks, such as fittings, joints of equipment, or air hoses that are frequently tugged on.

- Optimize system pressure to reduce energy waste that comes from running the compressed air system at a higher pressure than needed. This includes recommendations to lower the pressure and the temperature of the air intake. When pressure is too high, the high pressure can stress out a compressor’s components and reduce its lifespan.

- Switch equipment or steps in processes with compressed air to reduce energy loss. One organization kept water out of airlines by periodically opening these lines so that collected condensate water could be released. The MnTAP intern suggested new equipment that would minimize the time needed to keep these lines open to drain effectively, and thus, reduce the amount of compressed air that was also escaping during these openings.

Like compressed air leaks, leaks of heated air, cooled air, and steam can waste considerable energy and drive up costs for manufacturers. Here are some sealing recommendations that MnTAP interns often make outside of compressed air.

- Guard cooled air within freezers, coolers, and chilled rooms. This means replacing gaskets on freezers and coolers to ensure warmer air is not entering through them; installing polyvinyl chloride (PVC) strip curtain behind doors that often remain open for a while; and/or fixing gaps beneath doors to stop warm air from sneaking into freezers and chilled rooms.

- Seal gaps in the building envelope to prevent energy loss or stop the introduction of drafts into the facility. Dock leveler sweeps help doors achieve a tighter seal while spring-loaded hinges automatically close doors and minimize gaps between doors and walls.

- Install occupancy sensors on exhaust fan controls to keep temperature controlled air in rooms, such as restrooms, when no one is using them.

- Repair failed steam traps. Damaged steam traps do not reliably close after condensate is released, and this can lead to significant amounts of steam escaping. Steam is also very costly to produce. Prompt maintenance and repairs ensure that dirt, pressure surges, and deterioration of parts do not cause steam traps to fail.

Insulation

While sealing works by eliminating air leaks and reducing unwanted air exchange, insulation aims at slowing down heat transfer. Some common MnTAP intern activities regarding insulation include:

- Identify which equipment might require more insulation, and these included looking at hot oil tanks, walls between heated tank rooms, and spray dryers.

- Investigate what types of insulation might or might not work for facilities, and these included closed cell spray foam insulation and thermal insulating paint.

- Recommend adding lids to help trap heated air in storage tanks, sand heaters used for producing concrete, and dryers powered by natural gas. In addition, lids can keep heat from escaping through evaporation for hot water heaters and alkaline tanks.

- Recommend adding insulation on exposed pipes for heated air, steam, and refrigerant.

- Insulating boiler pipes can improve boiler efficiency and reduce natural gas use.

- Maintaining and repairing insulation on steam pipes was recommended by interns because the steam’s high heat can deteriorate insulation over time.

- Repairing missing or degraded pipe insulation for pipes both inside and outside a facility. PVC jacketing can help protect outdoor insulation from degrading due to ultraviolet radiation or UV.

- Recommend training staff members on best practices when they are loading product cases in walk-in coolers and freezers. Improper placement can cause cases to block the intake and disrupt the airflow pattern within cold rooms leading to insulation inefficiency.

Maintain existing systems and equipment

Maintenance involves continually keeping equipment in reliable working order as malfunctioning equipment is often energy inefficient. This section highlights maintenance recommendations, including repairing and cleaning, that can help equipment function at peak performance and save energy. MnTAP intern recommendations include:

- Cleaning the intake of air cooled condensers mounted on the roof. Air cooled condensers blow air across a network of tubing to expel heat created by hot refrigerant. If not cleaned regularly, dust or debris will accumulate in the unit’s intake and reduce its efficiency.

- Cleaning chiller tubing halfway through the cooling season or automatically could halt a buildup of fouling from the well water that runs through the tubes. This fouling impedes heat transfer and increases the energy costs for the facility.

- Repairing or replacing failed motors in air compressor systems promptly ensures that compressors can continually operate effectively and efficiently.

Investigate Recoverable or Renewable Energy Sources

A final category of best practices for companies and organizations to explore includes opportunities for energy recovery as well as on-site energy generation through by-product utilization or renewable sources. Solutions identified in this category can help maximize efficiency, reduce energy consumption and costs, and may present new revenue streams in special cases. Here are some recommendations from MnTAP interns that fit in this category:

- Install a combined heat and power system or cogeneration system. These produce electricity and energy from a single fuel source. Not only are they highly efficient and cost effective, but these systems can also reduce emissions. They may be especially attractive to facilities facing grid reliability concerns because they ensure that energy is being produced on site.

- Install energy recovery equipment on systems with ventilation. This can be an excellent way to minimize heating and cooling demands, reduce overall energy consumption, and maximize efficiency.

- Explore how organic wastes could be diverted to renewable energy production when source reduction solutions have been exhausted. At a brewery, a MnTAP intern recommended diverting off-spec liquid product to an ethanol plant or anaerobic digester for renewable energy production instead of the existing practice of sending this waste to drain. This presents both a potential revenue source and a solution to decreasing biochemical oxygen demand (BOD) loading in the facility’s wastewater.

- Install solar panels on the roof of facilities or offices that receive significant sunlight.

Incidentally, MnTAP can advise on energy recovery opportunities at your facility. For those interested in delving more into renewable energy sources, MnTAP recommends connecting with other organizations, such as the Center for Energy and Environment.

In conclusion, this article is the second and final part of introducing a framework to reduce energy use for manufacturers. Businesses and companies should not feel as if they must take all this on by themselves. Most of the strategies outlined here are what MnTAP staff work on every day, and MnTAP staff are available to carry out site visits and consultations. All MnTAP staff services are confidential, at no cost, and non-regulatory. When more in-depth assistance is needed, the MnTAP intern program provides extended, hands-on assistance for a nominal cost-share.

Author:

Jocelyn Leung- Communications Specialist

Contact

Matt Domski – Intern Program Manager

mdomski@umn.edu

612-624-5119

Events

Salt Symposium

Bolton & Menk

August 5, 2025, 8:00 AM – 4:30 PM CST

Livestream only, $160 (Early bird pricing ends June 30)

The 26th Salt Symposium will be held Tuesday, August 5th, 2025. It is a day-long virtual event bringing together professionals around the world to share their expertise on current research, planning, and initiatives surrounding chloride: including snow and ice management, low salt design, water softening, wastewater, and agriculture.

The Salt Symposium is an annual event focused on understanding the concerns, research, solutions, and management of chloride use and innovation that can move us to a lower salt future to improve community sustainability and protect vital freshwater systems and infrastructure. Learn More and Register.

Funding Opportunities

- Freight switcher locomotive grant (MPCA): Deadline is 4:00 pm CT on July 3, 2025.

- Environmental assistance loans for capital costs associated with environmental processes and technologies (MPCA & private financial institutions)

- Small business environmental improvement loans [0% interest for capital equipment purchases] (MPCA)

- Business Pollution Prevention Program [Up to $50,000 or up to 75% of project costs] (Ramsey/Washington Recycling & Energy and MN Chamber of Commerce Waste Wise): Consider this opportunity if your business uses or produces any of the following chemicals with volatile organic compounds (VOCs); perchloroethylene (PERC); trichloroethylene (TCE); ground level ozone; fine particulate matter (PM2.5); or hazardous air pollutants (HAPs).

- Safety Grant Program [Up to $10,000] (MNOSHA WSC): For projects designed to reduce risk of illness or injury to their employees. Applications are reviewed in two month durations.

- Funding for brownfield investigation (MPCA)