Compressed Air Systems

Approximately 70% of all manufacturers have a compressed air system. These systems power a variety of equipment, including machine tools, material handling and separation equipment, and spray painting equipment. Compressed air is one of the most expensive uses of energy in a manufacturing plant. About 8hp of electrical power is used to generate the electricity required for 1hp of compressed air, making it the least efficient and sustainable plant utility. While there are applications that require the use of compressed air, many uses of compressed air can be eliminated to save money. Calculating the cost of compressed air in your facility can help you justify system improvements that increase energy efficiency. This page offers tips for increasing your compressed air system’s efficiency and decreasing costs.

Approximately 70% of all manufacturers have a compressed air system. These systems power a variety of equipment, including machine tools, material handling and separation equipment, and spray painting equipment. Compressed air is one of the most expensive uses of energy in a manufacturing plant. About 8hp of electrical power is used to generate the electricity required for 1hp of compressed air, making it the least efficient and sustainable plant utility. While there are applications that require the use of compressed air, many uses of compressed air can be eliminated to save money. Calculating the cost of compressed air in your facility can help you justify system improvements that increase energy efficiency. This page offers tips for increasing your compressed air system’s efficiency and decreasing costs.

Check for and Repair Leaks

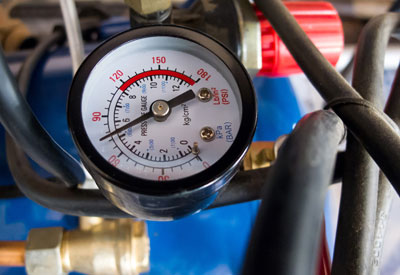

All compressed air systems have leaks, and large ones will be audible. Keep leaks to a minimum by correcting them as soon as they are found. Annually test your system during periods of non-production to determine its overall leak rate by looking at air loss from the supply tank. Compressed-air system leaks can be costly; a 1/8 inch diameter hole in a 100 psi system can cost you more than $1,200 per year in wasted energy, so it is worth maintenance time to fix all sizeable leaks. Even in noisy 24/7 environments ultrasonic leak detectors are available (and can be tested through MnTAP) that are a significant aid in homing in on leaks despite background noises.

Use Alternatives to Compressed Air

In some facilities, compressed air is used for operations because it is convenient to tap into as needed and doesn’t require the cost and time of electrical work. However, due to the extra electrical cost of using air compared to any other method of providing power, some operations can save significant dollars by getting away from uncontrolled usage and looking for cost effective alternatives. Some examples of alternative opportunities that might be found include:

- Using air conditioning or fans to cool equipment

- Applying a vacuum system instead of creating a vacuum using compressed air venturi methods

- Using blowers to provide cooling, agitating, or mixing, and to inflate or separate packaging

- Using blowers, brushes, or vacuum systems to clean or move parts

Limit Unregulated End-Uses

Not regulating end-of-use pressure can add to the cost of running your compressed air system by decreasing equipment efficiency below design. Installing a pressure regulator just prior to equipment can limit air demand and energy use, while potentially lengthening tool life and reducing maintenance costs.

Seek additional information about your system

Understanding your compressed air system and its intricacies can be an important step in understanding what energy conservation opportunities may exist. MnTAP’s fact sheet, Air Compressor Energy-Saving Tips, has more information about understanding and optimizing compressed air systems.

The following resources, tools, and case studies may help you determine the best options for optimizing your compressed air system. It is important to understand that the efficiency of your compressed air system is your responsibility. The most important efficiency improvements often require little capital to implement and may help you gain capacity without new equipment, so relying on equipment vendors to reliably provide the best solutions may not always be in your best interest.

Related Webinars

Pneumatic to Electric Tool

- Welcome/Introduction (00:00:00)

- Overview (00:02:53)

- Findings (00:07:28)

- Guide for Facilities (00:015:36)

- Calculator Tool Demonstration (00:16:15)

- Overview of Calculator (00:16:30)

- Basic Calculator (00:22:09)

- Advanced Calculator (00:30:28)

- Questions (00:40:28)

Resources

- MnTAP Pneumatic to Electric Tool Cost Calculator

- MnTAP Facilities’ Guide for Reducing Costs through Pneumatic Tool Replacement

This guide is intended to help facilities understand the benefits, barriers, and other important considerations for switching from pneumatic to electric power tools.

- MnTAP Fact Sheet: Air Compressor Energy-Saving Tips (2009). This fact sheet about air compressors will help you calculate their operating cost, understand your system, and identify energy efficiency strategies.

- MnTAP Source Article: Top Compressed Air Energy Saving Options (2006). Compressed air assessments reveal that facilities have common opportunities for energy efficiency improvements: storage, sequencing and removing inappropriate uses.

- MnTAP Intern Summary: Intern at Artic Cat Reduces Water, Energy, and Chemical Use (2009). The company increased their energy efficiency by identifying and repairing compressed air leaks and identifying appropriate shut down periods for their compressed air systems.

- Compressed Air Challenge Fact Sheets and calculation tools. The Compressed Air Challenge is a product-neutral industry collaboration with partial sponsorship by the US Department of Energy.

- Fact Sheet 1 – Assessing Compressed Air Needs[PDF 193KB]

- Fact Sheet 2 – Inappropriate Uses of Compressed Air[PDF 190KB]

- Fact Sheet 3 – Compressed Air System Audits[PDF 187KB]

- Fact Sheet 4 – Pressure Drop & Controlling System Pressure[PDF 186KB]

- Fact Sheet 5 – Maintenance of CA Systems for Peak Performance[PDF 189KB]

- Fact Sheet 6 – Compressed Air System Controls[PDF 201KB]

- Fact Sheet 7 – Compressed Air System Leaks[PDF 200KB]

- Fact Sheet 8 – Packaged Compressor Efficiency Ratings[PDF 181KB]

- Fact Sheet 9 – Compressed Air System Economics[PDF 190KB]

- Fact Sheet 10 – Heat Recovery with Compressed Air Systems[PDF 181KB]

- Fact Sheet 11 – Proven opportunities at the Component Level[PDF 198KB]

- S. DOE Office of Advanced Manufacturing Energy Efficiency & Renewable Energy: Best Practices for Compressed Air. Provides an assortment of tools and resources to help industrial end users achieve efficiency improvements and related cost savings.

MnTAP Case Studies

- Arctic Cat. A MnTAP intern helped the company reduce energy use from the paint line, reduce phosphorus discharges in the wastewater, and improve compressed air efficiency.

- Tennant Company. Waste and energy use were both reduced through a MnTAP intern project.

- K-Bar Industries & World Aerospace Corp (2005). MnTAP helped the two companies determine what opportunities were available for improving their compressed air systems.

- Johnson Screens (2011). There was an opportunity at this facility for a MnTAP intern to improve the compressed air system and the room ventilator.